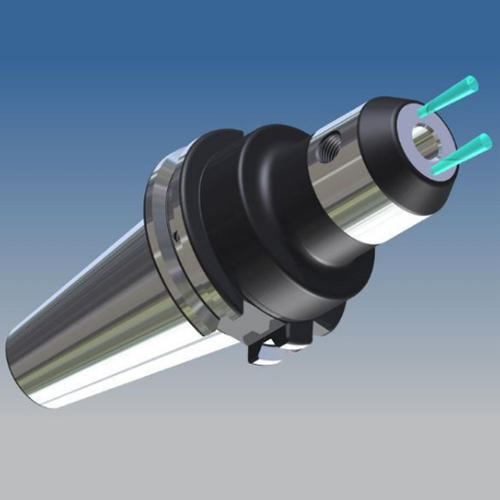

Heavy Collet Chuck

Heavy Collet Chuck Specification

- Cutting Accuracy

- 0.005 mm mm/m

- Material

- Others

- Hardness

- HRC 50-55

- Shape

- Cylindrical

- Features

- High precision concentricity, Quick change, Secure grip

- Machine Type

- CNC Machines, Milling Machines

- Coating

- Uncoated

- Operate Method

- Manual tightening with appropriate spanner/key

- Cutting Speed

- Applicable up to 8000 RPM RPM

- Length

- 100 mm to 160 mm (depends on model) Millimeter (mm)

- Drill Bits Types

- Compatible with ER collet drill bits

- Operation Type

- Clamping and Holding

- Cutting Force

- High clamping force

- Cutting Capacity

- 1-26 mm (varies by collet size)

- Cutter Type

- Holds End Mills, Drills, and Reamers

- Tool Type

- Collet Chuck

- Diameter

- Standard sizes: 16 mm, 20 mm, 25 mm, 32 mm Millimeter (mm)

- Maximum Torque

- 120 Nm N-cm

- Processing Type

- Turning, Milling, Drilling

- Corrosion Resistance

- Enhanced with anti-rust oil

- Surface Finish

- Polished

- Thread Type

- Metric

- Standard

- DIN 6499

- Balance Quality

- G6.3 at 12000 RPM

- Tool Holder Type

- ER Collet Chuck

- Runout Tolerance

- 0.005 mm

- Collet Range

- ER16 to ER40

- Packaging

- Individual protective box

- Recommended Use

- Industrial machining, Tool room operations

Heavy Collet Chuck Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 100 Pieces Per Week

- Delivery Time

- Week

About Heavy Collet Chuck

Product Specification

| Material | Alloy Steel |

| Tensile Core Strength | Min. 1200 N/mm2 |

| Hardness | 60+/-2 HRC |

| Minimum Order Quantity | 1 Number |

Product Description

Form:Deliivery in form AD, type B closed with releasable hadless screw

Application:For mounting streight shank tool in collets

Delivery:with ball bearing clamping Nut

Sizes Available:

- SK 30

- SK 40

- SK 50

Precision and Reliability

Engineered to DIN 6499 standards, this ER Collet Chuck delivers exceptional precision for demanding industrial applications. Its high concentricity and low runout tolerance ensure accurate machining, making it a preferred tool room solution. The sturdy alloy steel construction and manual tightening mechanism provide robust grip and secure tool holding, enhancing both safety and performance.

Versatile Application Range

Suitable for turning, milling, and drilling processes, the ER Collet Chuck accommodates a wide range of tooling, including end mills, drills, and reamers. Compatible with ER collet drill bits from 1 mm up to 26 mm capacity (depending on collet size), it offers quick changeability, supporting fast-paced production environments. Its adaptability extends across CNC and standard milling machines.

Durable Design and Enhanced Protection

With a polished, uncoated finish and advanced anti-rust oil treatment, the chuck resists corrosion for extended longevity. Each unit is packaged in an individual protective box, preserving its quality during transport and storage. The hardened alloy steel (HRC 50-55) and high balance quality (G6.3 at 12,000 RPM) ensure stable operation and prolonged tool life.

FAQs of Collet Chuck:

Q: How is the ER Collet Chuck installed and tightened during tool setup?

A: Installation involves inserting the appropriate ER collet into the chuck, followed by manually tightening the nut using a suitable spanner or key. Ensure the collet and tool are seated securely to achieve optimal clamping force and precision.Q: What types of tools and machining operations is this collet chuck suitable for?

A: This ER collet chuck is designed to hold end mills, drills, and reamers, and is ideal for turning, milling, and drilling operations on CNC machines and conventional milling equipment.Q: When should I choose an ER Collet Chuck with a polished finish and anti-rust oil?

A: Select an ER Collet Chuck with these features when your application demands enhanced corrosion resistance, a long service life, and consistent performance in tool room or industrial machining environments.Q: Where can this product be used within industrial settings in India?

A: The collet chuck can be utilized in CNC machining centers, milling machines, and tool rooms across manufacturing plants, workshops, and research facilities throughout India.Q: What is the recommended collet size range and cutting capacity for this chuck?

A: The chuck supports ER collets ranging from ER16 to ER40, with cutting capacities between 1 mm and 26 mm depending on the specific collet size installed.Q: What are the primary benefits of using this ER Collet Chuck in machining operations?

A: Key advantages include high precision concentricity (0.005 mm), robust clamping force, quick tool changes, secure grip, and reliable performance at speeds up to 8,000 RPM with minimal runout and superior corrosion resistance.Q: How does the individual protective packaging benefit distributors, exporters, and suppliers?

A: Packaging each chuck in a protective box ensures product integrity during transit and storage, facilitating safe handling for distributors, exporters, importers, suppliers, and traders in India.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pramet Tools Category

End Milling Cutters

Minimum Order Quantity : 10 Barrels

Processing Type : End Milling / Slotting / Profiling

Shape : Cylindrical with multiple flutes

Material : Others, High Speed Steel (HSS) or Solid Carbide

Coating : TiN (Titanium Nitride)

Weldon End Mill Holders Coolant Channels

Price 12000 INR / Piece

Minimum Order Quantity : 1 Piece

Processing Type : Assuring you best of series all the time

Shape : Round

Material : Stainless Steel

Er Sealed Collet For Cylindrical Shank

Price 600 INR / Piece

Minimum Order Quantity : 1 Piece

Processing Type : Assuring you best of series all the time

Shape : ROUND

Material : Steel

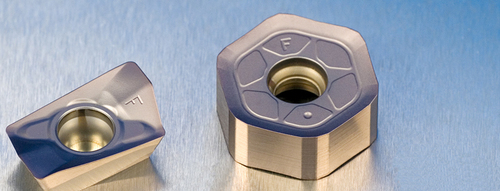

Heavy Indexable Cutting Insert

Price 1520 INR / Piece

Minimum Order Quantity : 10 Pieces

Processing Type : Assuring you best of series all the time

Shape : round &other

Coating : MTCVD

Send Inquiry

Send Inquiry