SOLID CARBIDE REAMER WITH CYLINDRICAL SHANK DIN 6535

SOLID CARBIDE REAMER WITH CYLINDRICAL SHANK DIN 6535 Specification

- Coating Type

- None / Optional (TiN, TiAlN, etc.)

- Hardness

- Up to 92 HRA

- Operate Method

- Manual or CNC machine operation

- Cutting Capacity

- Suitable for alloy steel, cast iron, non-ferrous metals

- Cutting Speed

- High (depending on material & size)

- Material

- Solid Carbide

- Length

- Overall length 60 mm to 150 mm

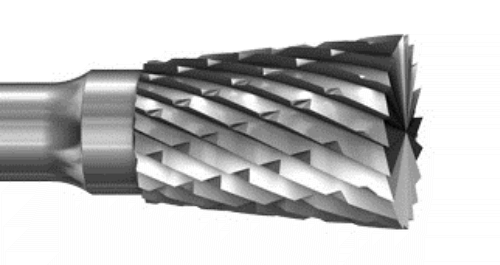

- Cutter Type

- Reamer

- Tool Type

- Reamer

- Cutting Force

- Low, due to stable geometry

- Coating

- Uncoated / optional coating

- Features

- Precision ground, excellent wear resistance, high dimensional accuracy

- Machine Type

- Conventional and CNC Machines

- Cutting Accuracy

- H7 tolerance (typical)

- Shape

- Cylindrical

- Drill Bits Types

- Straight or Spiral fluted

- Operation Type

- Rotary Cutting

- Diameter

- 3 mm to 20 mm (standard)

- Maximum Torque

- Depends on application and diameter

- Processing Type

- Finishing

- Tolerance

- Precision fit for engineering applications

- Number of Flutes

- 4 to 8 (dependent on diameter)

- Application

- Finishing and precision reaming

- Standard

- DIN 6535

- Cooling Method

- With or without coolant

- Usage

- Used in toolroom, automation, and production environments

- Shank Type

- Cylindrical Shank

- Flute Type

- Straight or Helical

- Surface Finish

- Bright

- Blade Size

- Varies as per diameter (commonly 3mm - 20mm)

- Reaming Direction

- Right hand cut

SOLID CARBIDE REAMER WITH CYLINDRICAL SHANK DIN 6535 Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 100 Pieces Per Day

- Delivery Time

- 1 Week

- Main Domestic Market

- All India

About SOLID CARBIDE REAMER WITH CYLINDRICAL SHANK DIN 6535

CARBIDE REAMER / SOLID / UNIVERSAL / HIGH-PERFORMANCE

Description

KOMET DIHART is expanding its solid carbide reaming range with a completely overhauled universal reaming tool, available from stock in the main dimensions both with H7 tolerance and in 1/100 dimensions.

The combination of knowledge and experience gained with the previous product line has enabled us to systematically develop the cutting geometry and achieve incredibly high cutting performance in various different materials even those hardened up to HRC62. At the same time, the modified cutting edge pitch reduces chatter marks and improves chip formation. In addition to optimal cutting edge cooling, the targeted coolant also aids smooth evacuation of chips that are formed. A high-performance coating completes the new design, and can be used for various different materials, thus also contributing to longer tool life, as a result of significant improved wear resistance.

These characteristics and properties combine to create the kind of precision for which KOMET is known on the market, as well as its high standards of dimensional accuracy and surface finish quality.

Precision Reaming for Every Engineering Need

The SOLID CARBIDE REAMER WITH CYLINDRICAL SHANK DIN 6535 delivers precise, high-quality finishing for demanding engineering applications. With diameters ranging from 3 mm to 20 mm and a choice of straight or spiral flutes, it achieves consistent H7 tolerance, making it suitable for critical fits in both manual and CNC settings. Solid carbide construction ensures excellent wear resistance, minimizing tool changes and maximizing productivity in toolrooms, automation, or production environments.

Versatile Performance and Compatibility

Engineered to suit a wide array of materialsincluding alloy steel, cast iron, and non-ferrous metalsthis reamer operates reliably under both coolant and dry conditions. Its compatibility spans across manual tools and advanced CNC machinery, with application in finishing and precision reaming. Optional coatings like TiN and TiAlN offer added performance, while the cylindrical shank per DIN 6535 standard facilitates secure, accurate clamping for stable reaming.

FAQs of SOLID CARBIDE REAMER WITH CYLINDRICAL SHANK DIN 6535:

Q: How does the SOLID CARBIDE REAMER WITH CYLINDRICAL SHANK DIN 6535 achieve such high precision?

A: This reamer is manufactured from solid carbide, ensuring exceptional rigidity and dimensional stability. Its precision grinding, coupled with optimized geometry (straight or helical flutes), allows it to achieve tight tolerances like H7, crucial for engineering fits requiring high accuracy.Q: What applications is this reamer best suited for?

A: The tool is ideal for finishing and precision reaming tasks in toolroom work, automated assembly lines, and high-volume production environments. It is especially effective for components needing superior surface finish and accurately sized holes, such as those made from alloy steels, cast iron, and non-ferrous metals.Q: When should straight versus spiral flutes be used?

A: Straight flutes are generally recommended for reaming through holes and non-interrupted cuts in harder materials, while spiral flutes (helical) are preferable for blind holes and soft or ductile metals, as they aid chip evacuation and reduce cutting forces.Q: Where can these reamers be used in terms of machinery?

A: They are compatible with both conventional and CNC machines, making them suitable for a wide spectrum of manufacturing environments across India, from small workshops to advanced automation facilities.Q: What are the benefits of optional coatings on these reamers?

A: Optional coatings like TiN or TiAlN enhance tool life, increase resistance to wear and heat, and can improve performance in challenging materials or high-speed operations. Choosing the appropriate coating depends on the specific material being machined and application demands.Q: How does the cooling method affect the reaming process?

A: These reamers can be operated with or without coolant. Using coolant improves tool life, chip removal, and surface finish, especially under high-speed or heavy-duty conditions. Dry cutting is suitable for certain materials or when coolant application is impractical.Q: What is the main benefit of using a solid carbide reamer over other materials?

A: Solid carbide reamers offer superior hardness (up to 92 HRA), maintain sharp cutting edges longer, and allow higher cutting speeds, all contributing to increased productivity, lower cutting forces, and excellent dimensional reliability even under extended use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Komet Tools Category

Indexable Inserts

Price 1500 INR / Piece

Minimum Order Quantity : 10 Pieces

Shape : tranglar

Processing Type : Assuring best of series all the time

Tungsten Carbide Cutter

Price 2500 INR / Piece

Minimum Order Quantity : 1 Piece

Diameter : 6mm Millimeter (mm)

Shape : round

Fine Boring Tool

Price 40000 INR / Piece

Minimum Order Quantity : 1 Piece

Diameter : 1mm Millimeter (mm)

Shape : round

Processing Type : Assuring you best of series all the time

Spherical Cutter For Universal Use

Price 5000 INR / Piece

Minimum Order Quantity : 1 Piece

Diameter : 8mm60mm Millimeter (mm)

Processing Type : Assuring you best of series all the time

Send Inquiry

Send Inquiry