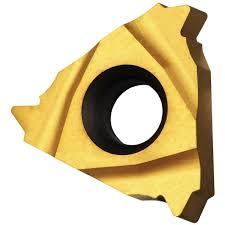

Threading Holder

Threading Holder Specification

- Features

- Durable, High Wear Resistance, Replaceable Inserts

- Hardness

- 58-62 HRC

- Coating

- Uncoated

- Cutter Type

- Thread Cutting

- Tool Type

- Threading Tool Holder

- Operation Type

- Threading Operation

- Cutting Speed

- Medium to High

- Cutting Force

- Optimized for rigid threading

- Cutting Accuracy

- High Precision

- Shape

- Rectangular

- Cutting Capacity

- For threading internal and external threads

- Length

- 100-180 mm

- Machine Type

- Lathe, CNC Turning Centers

- Material

- High-Speed Steel (HSS)

- Operate Method

- Manual and Machine Operated

- Diameter

- Varies (commonly 12-25 mm)

- Maximum Torque

- Up to 200 Nm

- Processing Type

- CNC and Conventional

- Temperature Resistance

- Up to 600°C

- Weight

- Approx. 0.5-1.2 kg

- Application

- Suitable for ferrous and non-ferrous metals

- Corrosion Resistance

- Yes

- Compatible Insert Types

- ISO-standard threading inserts

- Surface Finish

- Smooth ground finish

- Clamping Mechanism

- Screw Clamping

- Shank Size

- Standard

- Blade Size

- Standard (varies as per holder size)

Threading Holder Trade Information

- Minimum Order Quantity

- 10 Barrels

- Supply Ability

- 100 Barrels Per Week

- Delivery Time

- 1 Week

About Threading Holder

We are a remarkable entity, engaged in exporting and supplying a superior assortment of Threading Holder. This Delivers high metal removal rates and high reliability, even in challenging conditions such as complex tool paths and deep cavities. It is manufactured using optimum quality materials in accordance with set industry norms. In order to maintain quality, this is stringently tested on several quality parameters, before dispatching from our end. Moreover, this Threading Holder is available with us in different specifications at affordable prices.

Features:

- Easy to install

- Durable finish standards

- Optimum strength

Specification

| Color | Black |

| Material | Steel |

| Length | 100-200 mm |

| Radial Tolerance | 0.03 mm |

| Tool Code | Description | Rate/Approx |

| SER/L 2020 K 16 | Threading holder dia 20 | 7160 |

| SER/L 2525 M16 | Threading holder dia 16 | 7360 |

| SER/L 3225 P 22-A | Threading holder dia 32 | 8560 |

| SIR/L 0010 K 11-0 | Threading holder dia | 7440 |

| SIR/L 2532 S 22-A | Threading holder dia 25 | 12000 |

Optimized for Precision Threading

This threading holders high-precision cutting capability ensures accurate thread profiles for both internal and external operations. Its optimized rigidity and clamping efficiency deliver clean cuts without deformation, making it indispensable for industries requiring precision such as automotive, aerospace, and manufacturing.

Durability and Performance

Constructed from premium high-speed steel and featuring a smooth ground finish, the holder offers outstanding wear and corrosion resistance. The robust design facilitates high cutting speeds and torque up to 200 Nm, ensuring longevity and dependable results in demanding machining environments.

Versatile Compatibility and Application

Supporting ISO-standard threading inserts and standard shank sizes, this holder is compatible with a variety of CNC lathe machines and conventional turning centers. Its design makes it suitable for threading applications on different metals, enhancing its versatility and appeal for distributors and traders across India.

FAQs of Threading Holder:

Q: How does the screw clamping mechanism enhance the reliability of the threading holder?

A: The screw clamping mechanism secures ISO-standard inserts firmly, minimizing vibration and ensuring stable tool positioning during threading operations. This contributes to greater precision and reduced risk of insert displacement during high-torque, high-speed applications.Q: What insert types are compatible with this threading holder, and how do they impact versatility?

A: This holder accommodates ISO-standard threading inserts, which are widely available and interchangeable. This compatibility allows users to perform various thread profiles efficiently, enhancing operational flexibility across multiple machine types and threading applications.Q: When is the optimal time to use this threading holder within a manufacturing process?

A: The threading holder is best utilized during the threading phase of part manufacturing, whether for internal or external threads. Its high wear resistance, accuracy, and medium to high cutting speeds make it optimal for both batch and continuous production environments.Q: Where can this threading holder be applied, and which machines is it suitable for?

A: This holder is suitable for use on CNC turning centers and conventional lathe machines. Its rugged design allows it to perform reliably in diverse industrial settings, including workshops and manufacturing plants dealing with ferrous and non-ferrous metals.Q: What benefits does the high-speed steel material and smooth ground finish offer?

A: High-speed steel provides excellent hardness (58-62 HRC) and heat resistance (up to 600C), while the smooth ground finish reduces friction and wear. Together, these features extend tool life and maintain thread quality over prolonged usage.Q: How do the corrosion and wear resistance properties affect tool longevity?

A: The holders corrosion and wear resistance capabilities protect it against environmental damage and abrasion during threading, extending its service life and enabling consistent high-quality results even under intense machining conditions.Q: What is the process for replacing the threading inserts, and is it suitable for both manual and machine-operated applications?

A: To replace inserts, simply loosen the screw clamp, swap the ISO-standard insert, and retighten the clamp. This straightforward process is designed for ease of use, making the holder suitable for both manual and machine-operated threading applications in varied industrial settings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pramet Tools Category

Pramet Grooving Insert

Price 1810 INR / Piece

Minimum Order Quantity : 5 Pieces

Processing Type : Assuring you best of series all the time

Diameter : 1.60mm Millimeter (mm)

Shape : trangular

HNGX Inserts Cutting Tools

Price 1500 INR / Piece

Minimum Order Quantity : 10 Pieces

Processing Type : Assuring you best of series all the time

Diameter : 610MM Millimeter (mm)

Shape : round

Pramet Indexable Lathe Tool Insert Cnmg 120408E-M T8330

Price 896 INR / Piece

Minimum Order Quantity : 10 Pieces

Processing Type : Assuring you best of series all the time

Diameter : 5.16 mm

Shape : square

Collet Chuck

Price 4000 INR / Piece

Minimum Order Quantity : 1 Piece

Processing Type : Assuring best of series all the time

Diameter : 69871CCOZ

Send Inquiry

Send Inquiry